Description

BUILT TO ORDER, PLEASE ALLOW UP TO SIX WEEKS LEAD TIME

NEW running upgrades for 2025!

- We don’t stop improving- EVER.

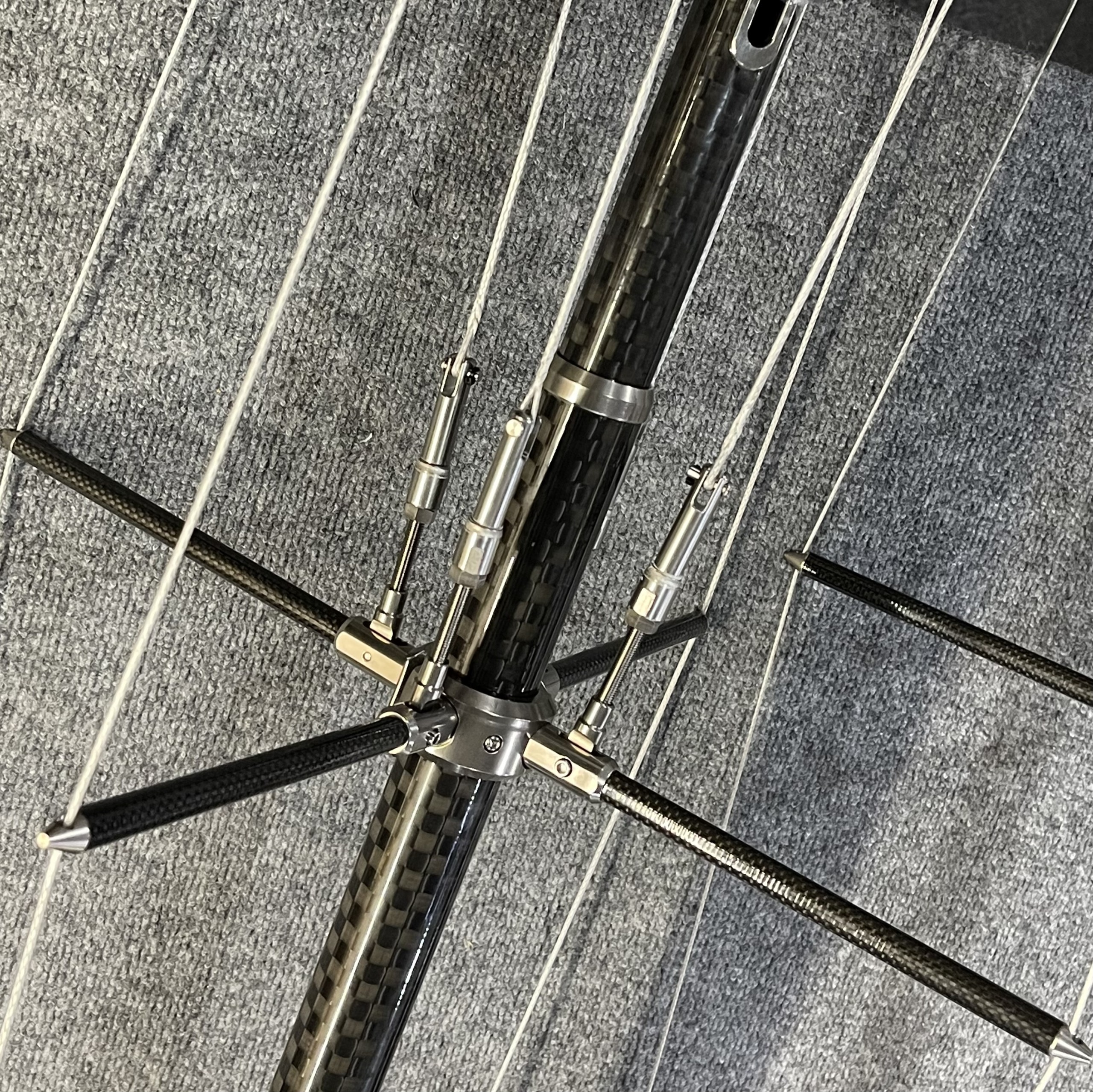

- Our own 100% machined and polished corrosion-proof, maintenance-free titanium tensioning adjustment system,

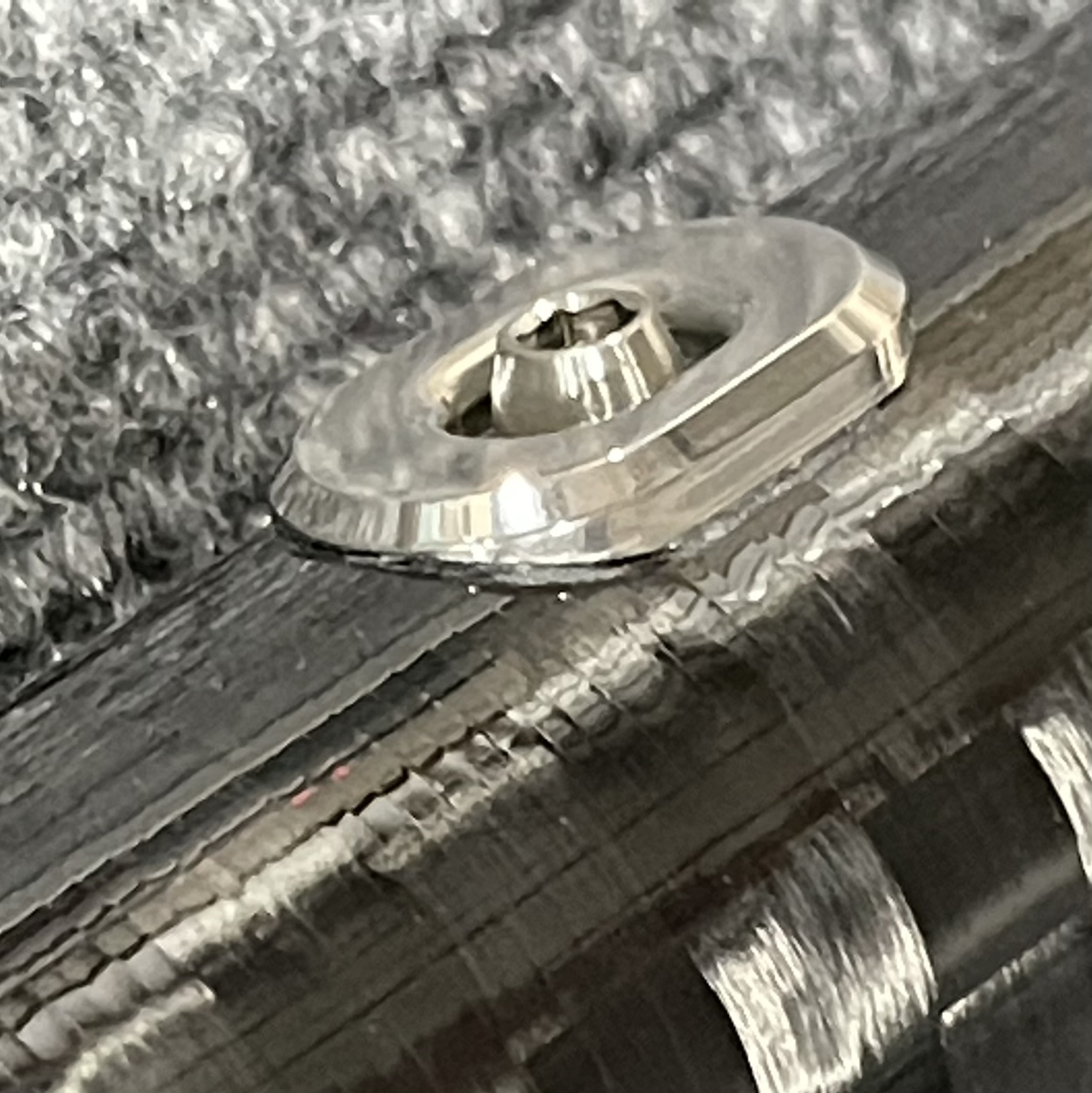

- 75% increase in support standoff tension pressure vs traditional aluminum with stainless cable-stayed spreader supported poles

- UV-proof 3k twill exterior carbon fiber ply is covered with thick single-phase (no separate clearcoat to maintain gloss and UV protection) Awlgrip for clear, white and custom colors,

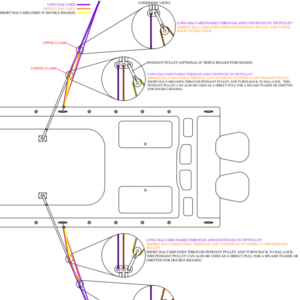

- String lines without any tools- just push the line down the pole interior from its respective exit, and it will come out of the titanium entry on its own, and

- Quieter operation.

American-made craftsmanship is what these flagship outriggers are. Please understand these aren’t for you if you want to put them into the same league as cheaper mass-produced outriggers. All the parts of these outriggers are slowly machined-from billet titanium that’s then tediously finished and polished. All the span sections and base structure are laid up with proprietary carbon fiber schedules, coatings and adhesives. Each time we have made a new industry disruptive outrigger model, the technology didn’t come from profit maximization or off-shored contract manufacturers. We constantly listen to customers and implement running improvements into what we build one set at a time, and that’s what these products are. The goal not only with each batch of parts but literally each serialized outrigger is to “build the best outrigger possible.” These models do not contain cheap materials found in something meant to get a product into a lower price point or “mid tier market.” We couldn’t lifetime warranty the product in such an unforgiving world if we approached it that way! .

We have been building internally rigged carbon fiber outriggers since 2015. Features include:

- ultra-stiff carbon fiber,

- new, highly refined, polished, machined titanium halyard management hardware bonded to carbon fiber without use of mechanical fasteners, which will eventually fail over time,

- Completely maintenance free, stain and corrosion proof design,

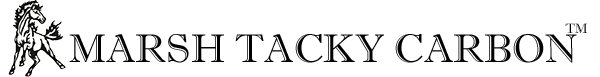

- Modular connectivity and support structure utilizing machined titanium allows not only for disassembly of poles for fast and easy shipping but also for an independently adjustable twist angle of each pole segment (point each halyard exit where you’d like, e.g.: point your short and medium exits at the cockpit, and point your long rigger exits at the flying bridge),

- The modular design also allows for replacement of impact-damaged sections or components without freight to and from our facility of an entire fixed length pole like in the past, and upgrading to longer lengths and/or addition of spreader support system upgrades without purchase of an entirely new set is possible,

- Dyneema support lines are fraction of the weight of traditional stainless cables and there’s no more constant fighting of an electrolysis nightmare thanks to titanium,

- GoPro or other cameras accessories can be mounted directly to the outriggers’ tips via 1/4″ – 20 tapped threads in the machined titanium tips,

- NO maintenance required to keep our LIFETIME WARRANTY,

- MADE IN THE USA,

- Price is for set of two poles,

- Email or call us for quotes on custom pole or hardware colors, custom lengths or base diameters, or any other needs,

- UNSURE ABOUT YOUR BASE SIZE OR IN NEED OF CUSTOM? Just use our Outrigger Mount Size Reference Page

Please watch this video (2022 finish shown) for explanation of some key features of our XTS outriggers